Band Sealers | AIE, Sealer Sales | New & Used

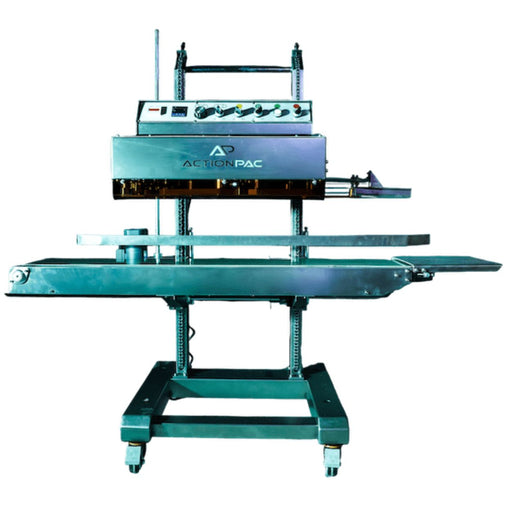

Sealer Sales HL-M1120LD & HL-M1120LD-LtoR Vertical Band Sealer (Right to Left & Left to Right)

This vertical band sealer is designed vertically to quickly and efficiently seal any thermoplastic material, including PE, PPE, stand-up pouches, g...

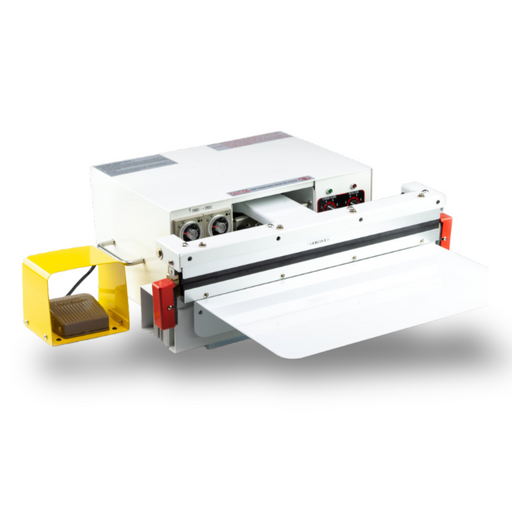

View full detailsSealer Sales CBS-Series Horizontal Band Sealer

Light Duty Right to Left Band Sealers with a Great Value Proposition This light duty Right Left Band Sealer is available in a horizontal model CBS-...

View full detailsActionPac Seal-E-7 Bag Sealer

Perfectly seals any style of coffee bag every time. Can handle the toughest packaging materials. Equipped with advanced technologies for precise s...

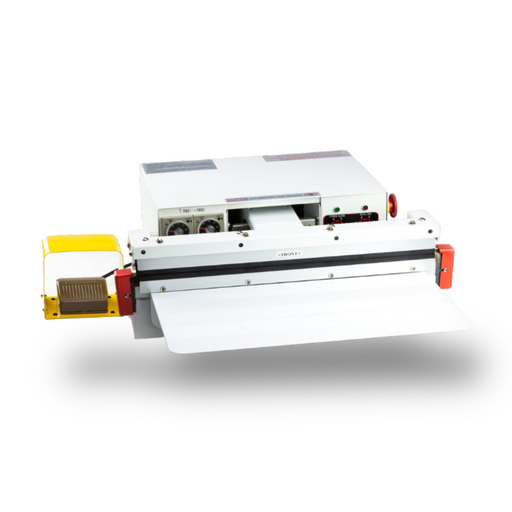

View full detailsSealer Sales FR-Series Horizontal Band Sealer: Left to Right

Light Duty Left to Right Band Sealers with a Great Value Proposition This light-duty Left to Right Band Sealer is available in a horizontal model F...

View full detailsAIE GA Series Gas Flush Vacuum Sealers

The AIE GA Series is a collection of Gas Flush Vacuum Sealers. Their sturdy construction makes them perfect for most applications. These units have...

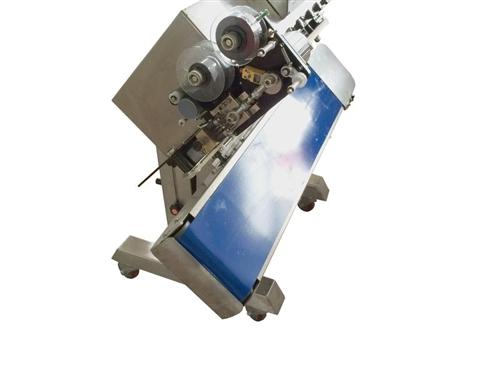

View full detailsSealer Sales FR-770II Vertical Continuous Band Sealer: 8mm Seal

Suitable for sealing all types of plastic materials and bags. It is one of our most popular band sealers with a great value proposition. Can seal...

View full detailsSealer Sales HLM Series Horizontal Left Feed with Dry Ink Coding

This band sealer model HL-M810I is a Left to Right feed band sealer and uses dry ink coding to print numbers or letters on the seal line. Also ava...

View full detailsSealer Sales CBS-Series Horizontal with Vertical Kit Band Sealer

Suitable for sealing all types of plastic materials and bags. This is a popular band sealer with a great value proposition. The CBS-880II can se...

View full detailsSealer Sales FRM-1010I - Horizontal Dry Ink Coding Band Sealer

The FRM-1010I Horizontal Dry Ink is the newest addition to Sealer Sales horizontal band sealer product line, and provides the best combination of e...

View full detailsSealer Sales HR-MV980ZQ Horizontal Band Sealer Right Feed with Dry Ink Coding

Our HR-MV980ZQ is a stainless steel, high-quality horizontal band sealer equipped with a nozzle-type vacuum device designed to remove excess air fr...

View full detailsSealer Sales FRM-1010I-20mm Horizontal Band Sealer Right Feed

Our newest addition to our band sealer product line provides the best combination of elegance and functionality in one unit. FRM-1010 provides a 1...

View full detailsSealer Sales CBS-880I-220V Horizontal Band Sealer Embossing Right Feed

Suitable for sealing all types of plastic materials and bags. One of our most popular band sealers with a great value proposition. Can seal 20-26 6...

View full detailsSealer Sales HLC-1120LD Vertical Right Feed Adjustable Sealing Head Trimmer

HLC-1120LD is suitable for sealing all types of thermoplastic materials and bags. This unit is equipped with a trim scrap system for trimming exces...

View full detailsSealer Sales FRM-1010II Impresse Vertical Right Feed Dry Ink Coding 15mm Seal Width

Our newest addition to our band sealer product line provides the best combination of elegance and functionality in one unit. FRM-1010 provides a 1...

View full detailsSealer Sales HLM Series Vertical Left Feed With Dry Ink Coding

HL-M810II is similar to CBS-880 except that the unit feeds from left to right and is equipped with a hot ink coding imprinter to print a date, expi...

View full detailsSealer Sales CBS-640 Portable Continuous Band Sealer

Designed for businesses that need a powerful sealer without taking up extra space, the CBS-640 is compact, lightweight (just 12 pounds), and packed...

View full detailsSealer Sales HRS-255 Rotary Horizontal Fully Enclosed Left Feed Band Sealer

Our newest addition to our band sealer family is the HRS-255 rotary band sealer. This sealer is ideal for sealing paper-plastic packages such as Ty...

View full detailsSealer Sales FRM-1120C Horizontal Band Sealer - Right to Left - Tilt Head - Dry Ink

The FRM-1120C is designed to quickly and efficiently seal any thermoplastic material, including PE, PPE, stand-up pouches, gusseted bags, and moist...

View full detailsSealer Sales FRS-1120W Horizontal Band Sealer: Right to Left, Tilting Head, Color Printing

This FRS-120W horizontal band sealer is designed to quickly and efficiently seal any thermoplastic material including PE, PPE, stand up pouches, gu...

View full detailsSealer Sales 20" Retractable Nozzle Vacuum Sealer (AVS-20, AVN-20, CAVS-20 & CAVN-20)

Offered in our most popular 20" seal length, this is the choice Vacuum sealer for the widest range of clientele. 4 Model Options: AVS-20: Vacuum O...

View full detailsAIE B7202 Industrial Horizontal Standing Band Sealer Left to Right Direction

The AIEB7202 Industrial Heavy Duty Horizontal Band Sealer is ideal for sealing plastic bags of virtually any size and length. The AIEB7202 Band Se...

View full details

No more pages to load

About Band Sealers | AIE, Sealer Sales | New & Used

Our stainless steel industrial grade band sealers are ideal for sealing thermoplastic materials (PP, PE, laminates) of any size and length. We carry both horizontal band sealers (bags lay flat on the conveyor) and vertical band sealers (bags are in a standing position on conveyor). Speeds of band sealers are considerably faster than other types of sealing (about 26 bags/minute).

Three categories for consideration of which model you need based on number of bags you seal daily and the durability and mobility options of the construction of the model.

LIMITED: About 1000 bags a day

Single bag 2.2 lbs and overall load 6.5 lbs

Machine stationery, probably on bench with vertical bag length up to 10.6"

MEDIUM BAG: About 1000-2500 bags/daily

Single load 5-12 lbs and overall 16-33 lbs

Machine portable options

*HEAVY BAG: *Special Order 9-11 weeks

Single Load about 22-44 lbs and overall load 66-132 lbs

Machine weight 330-500 lbs with larger dims

Questions to think about:

What might you consider in choosing a band sealer for your sealer?

Band sealers can seal 3mil-10mil bags with about any type of thermoplastic material: PE, PPE, standup pouches, gusseted bags and moisture barrier bags. The width of the bag is not important because the bags are put on a conveyor.

Do you need a horizontal or vertical sealer?

Horizontal is needed if the pouch is laid flat; vertical sealers seal smaller pouches AND if the stand up type of pouch is longer than the width of conveyor.

How does the height of the bag affect the sealing?

The height of the bag affects the choice of horizontal or vertical sealer. If the bag is longer than the width of the conveyor, it is wise to use a vertical sealer.

What about the width of the seal?

Comes with 8 inch seal but the 880 and 770 models (Light Load) carry a 15 mm seal.

Do you want any printing on the bag?

Dry ink or embossing are available. Embossing is best for foil bags. Dry ink uses a roller with heat activated transfers.

What direction to use in sealing process?

Your plant design or staff using the machine may contribute in the decision to use either left to right or right to left.