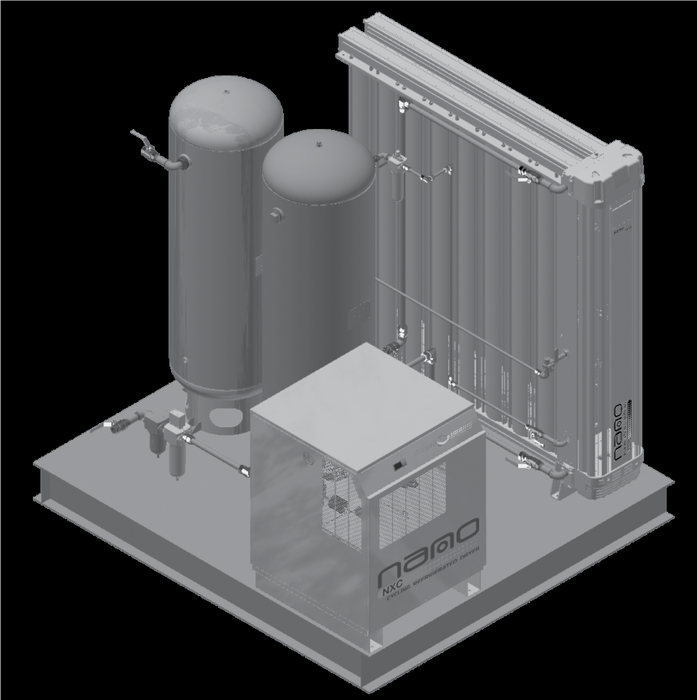

Gen2 i4.0 Nitrogen Generators - New

Click Here to get an estimated idea of crate & freight cost for this product.

Why a Quote?

Basic Info

Description

Specifications

Key Features

Sales, Inspection and Relocation

Alternatives of Gen2 i4.0 Nitrogen Generators - New

About Nano

Nano-Purification Solutions designs and manufactures advanced compressed air and gas purification systems. Serving industries like pharmaceuticals, food, and electronics, they offer nitrogen and oxygen generators, dryers, and filtration equipment. With a focus on customization, innovation, and global service, Nano delivers high-performance solutions that minimize downtime and boost efficiency. Now part of the Atlas Copco Group, they continue to lead in clean air technology.

Nano-Purification Solutions designs and manufactures advanced compressed air and gas purification systems. Serving industries like pharmaceuticals, food, and electronics, they offer nitrogen and oxygen generators, dryers, and filtration equipment. With a focus on customization, innovation, and global service, Nano delivers high-performance solutions that minimize downtime and boost efficiency. Now part of the Atlas Copco Group, they continue to lead in clean air technology.

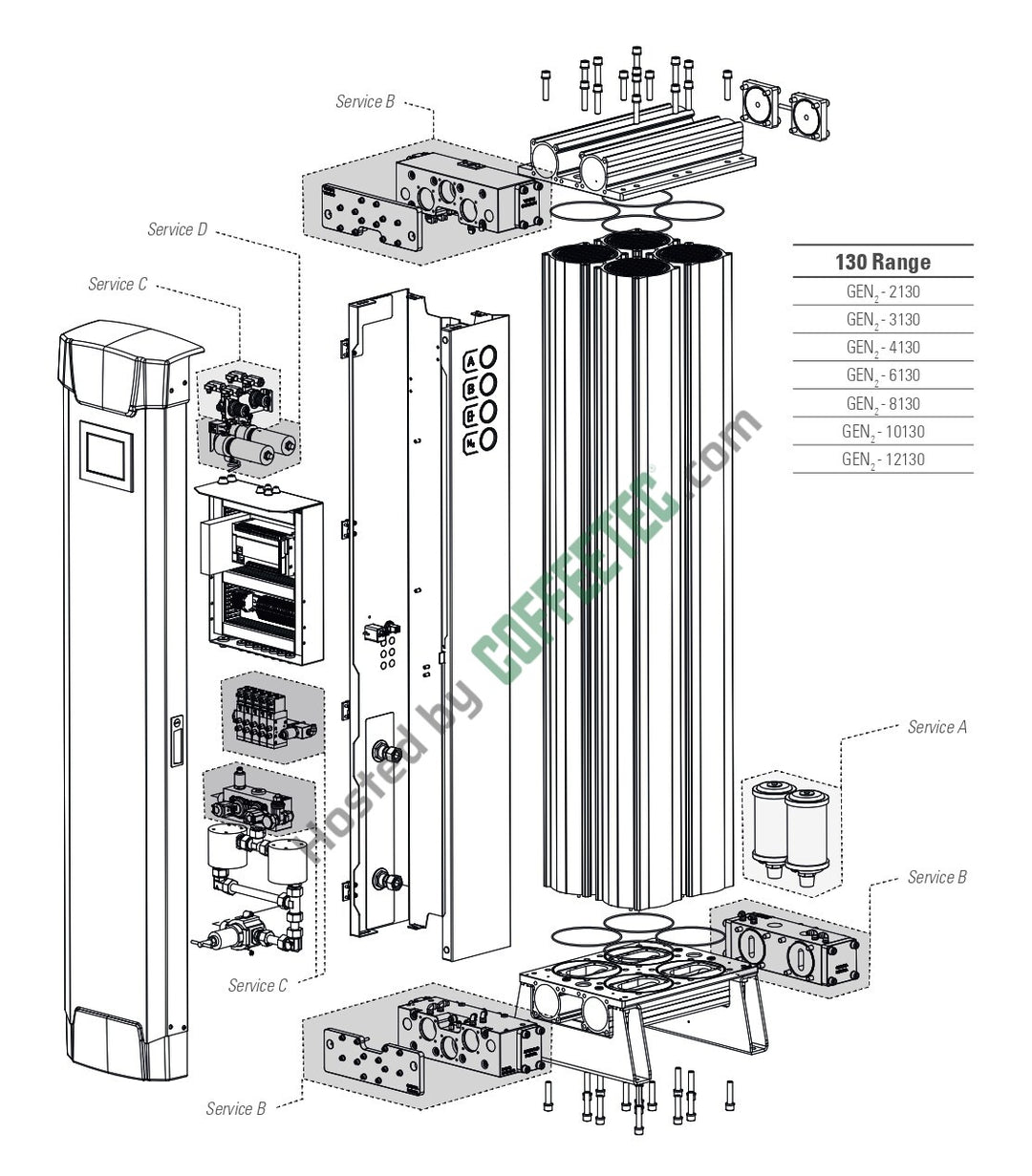

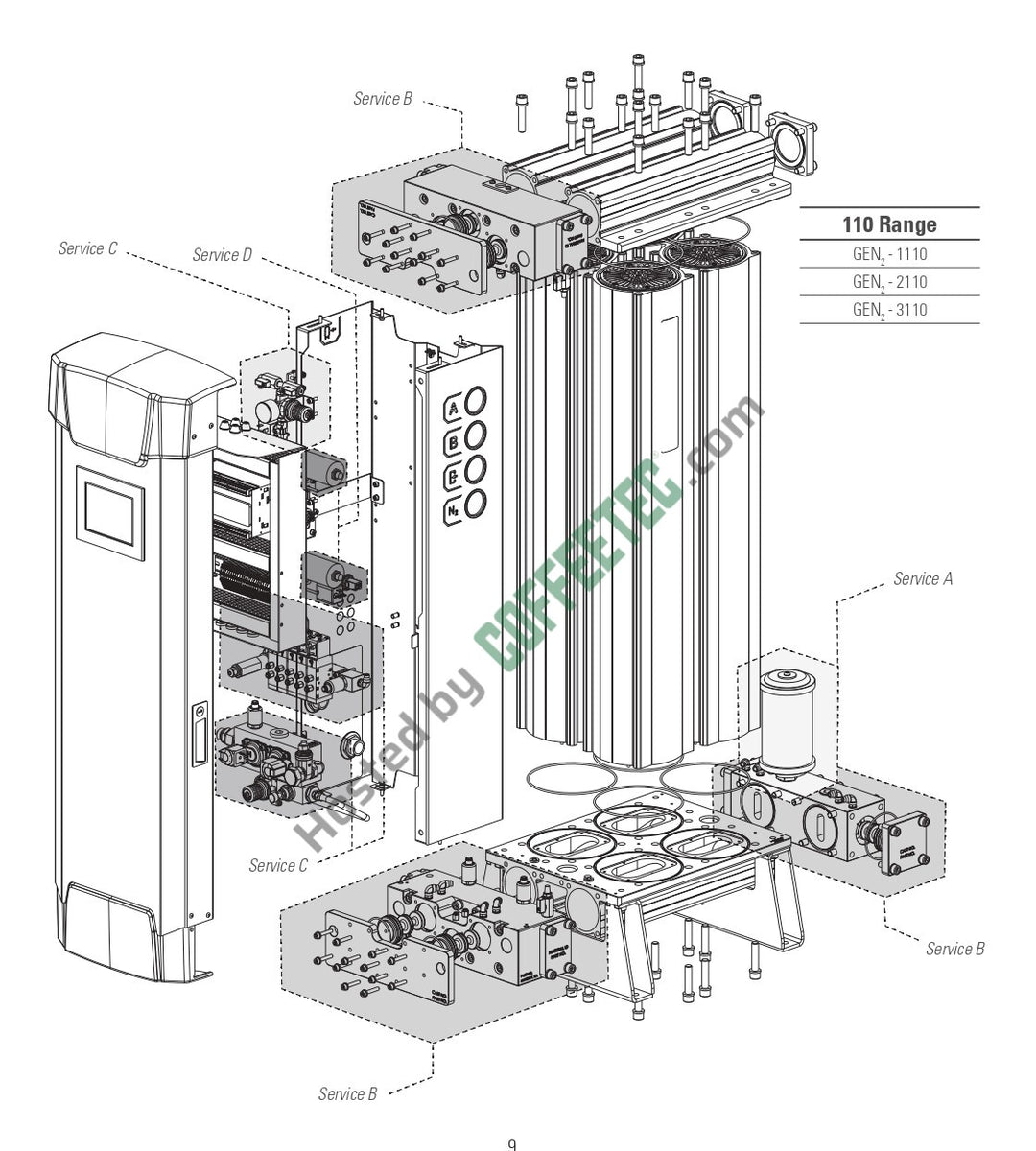

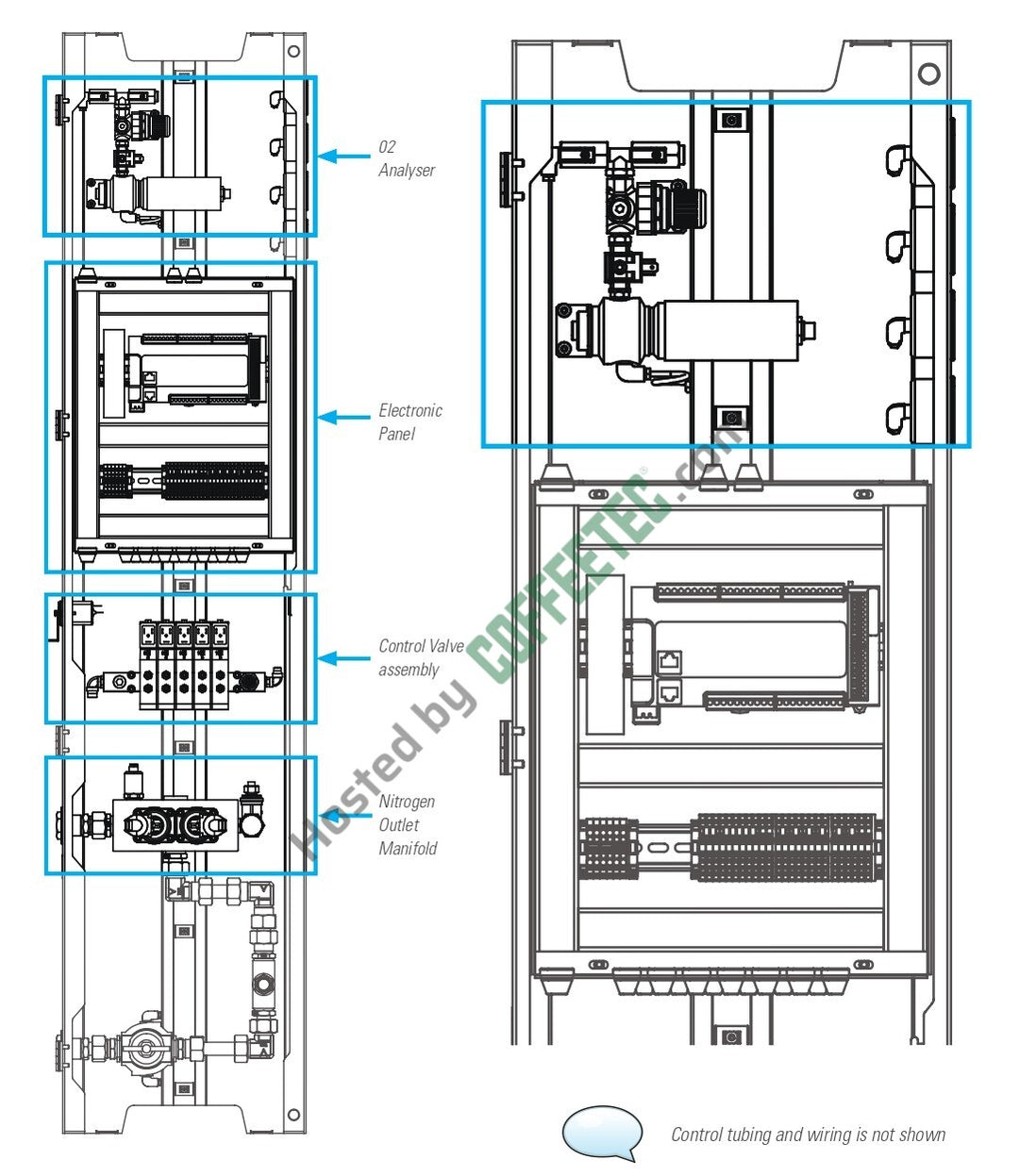

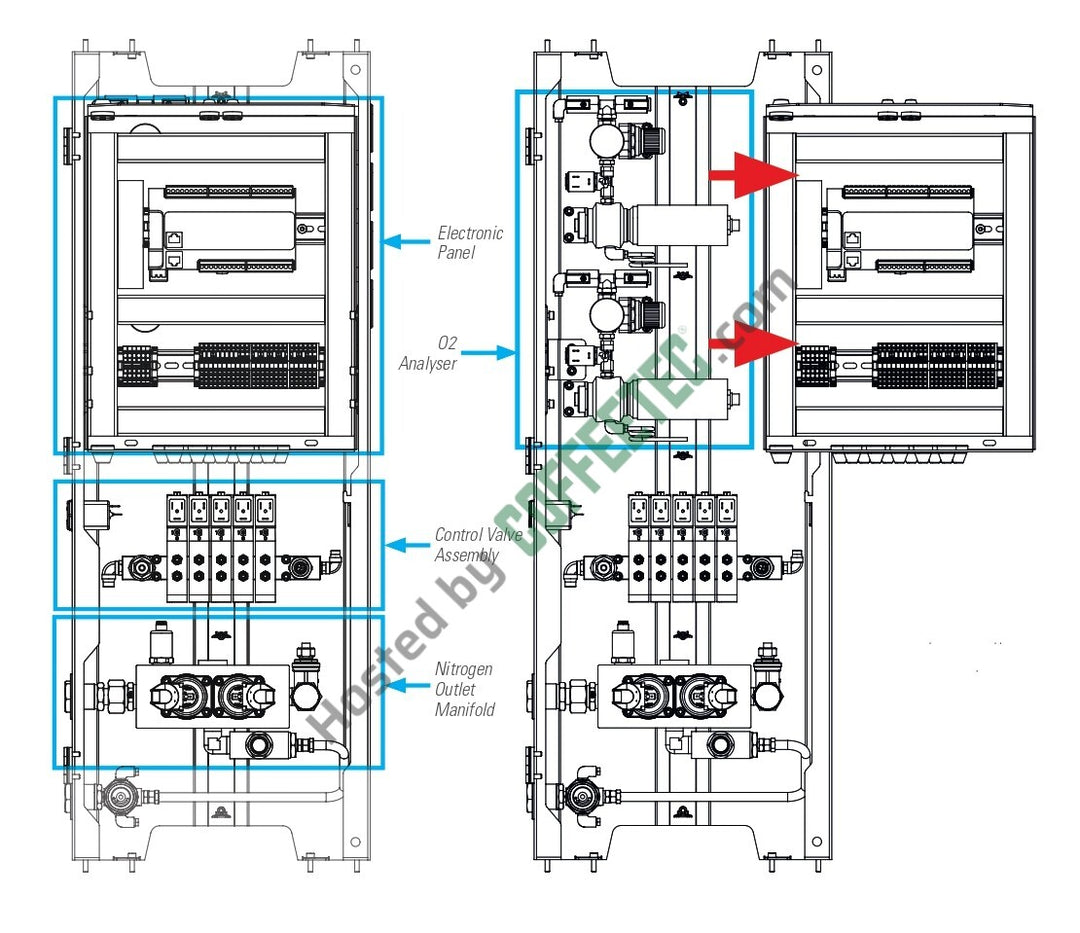

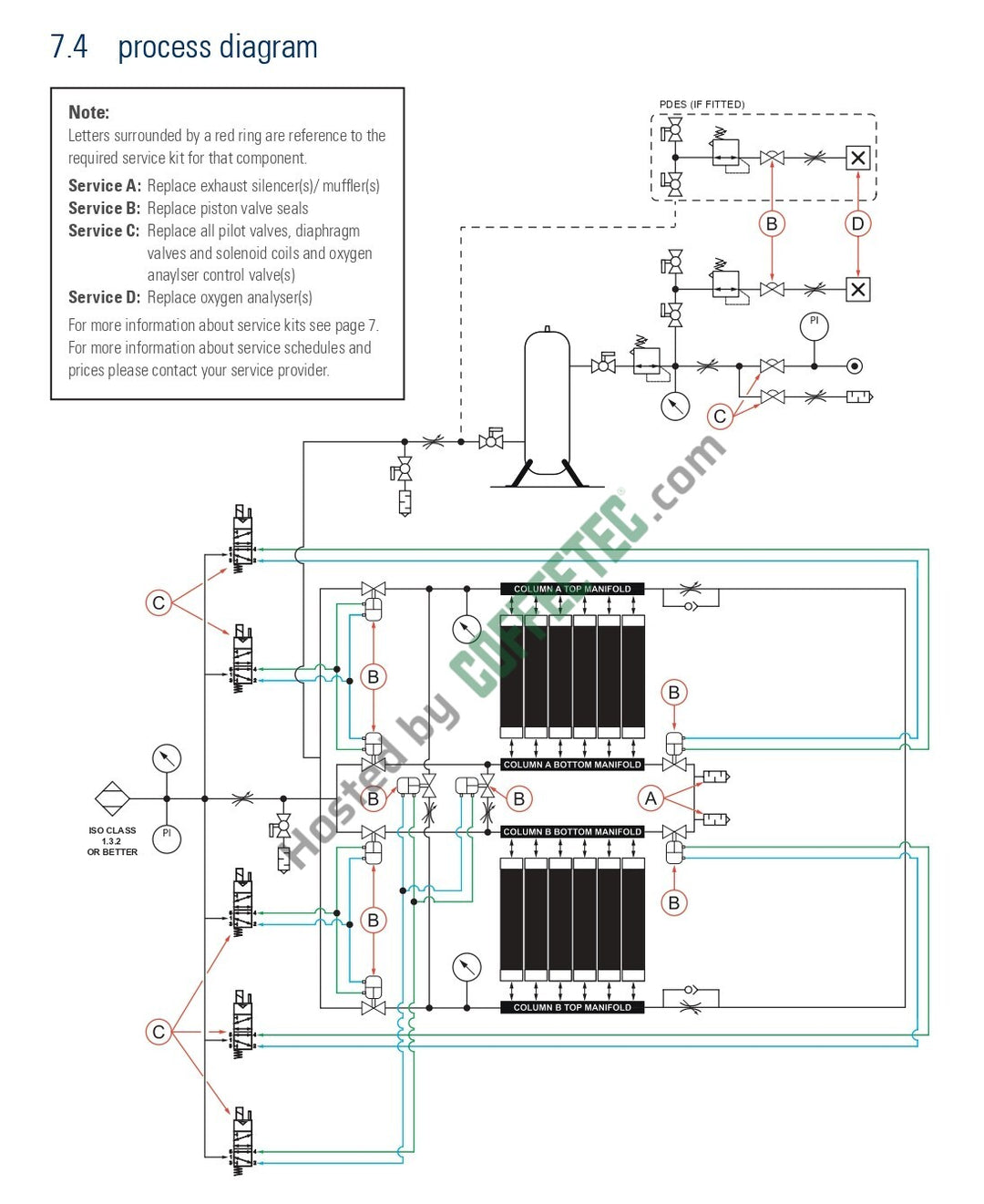

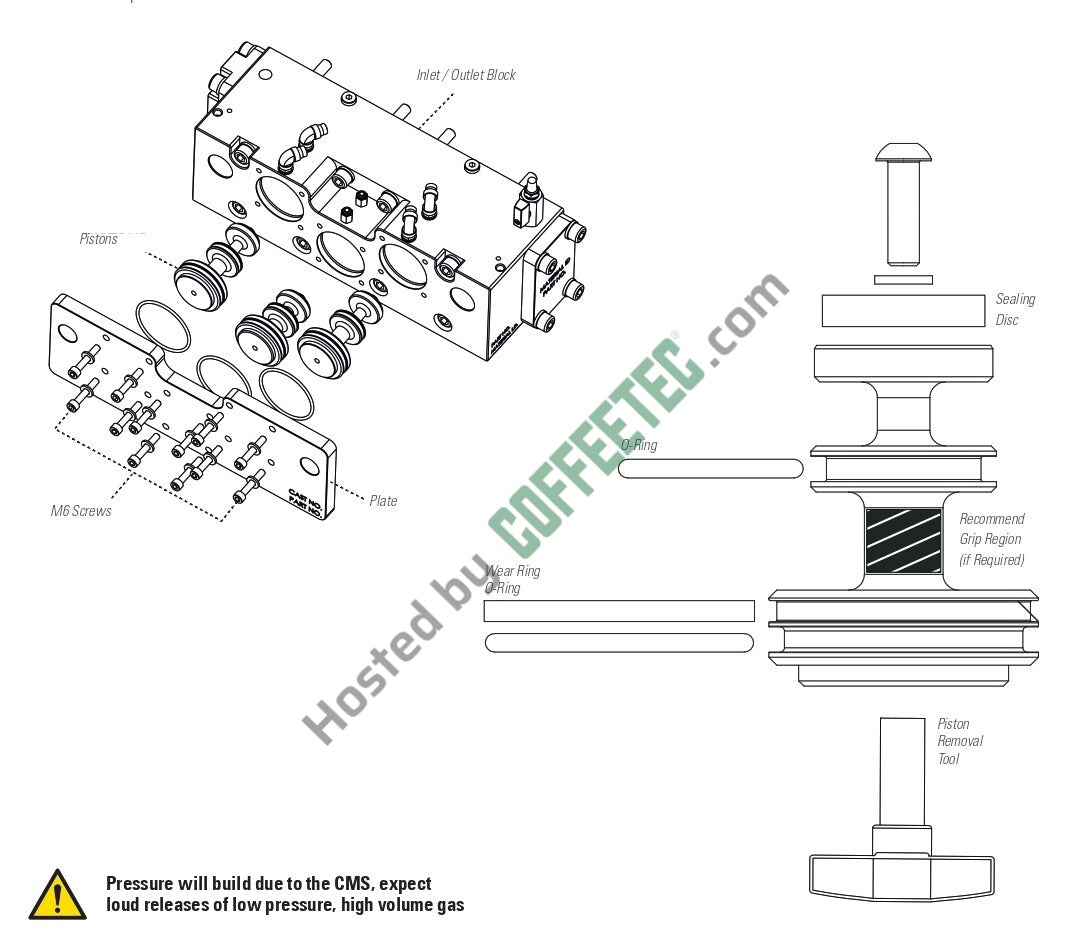

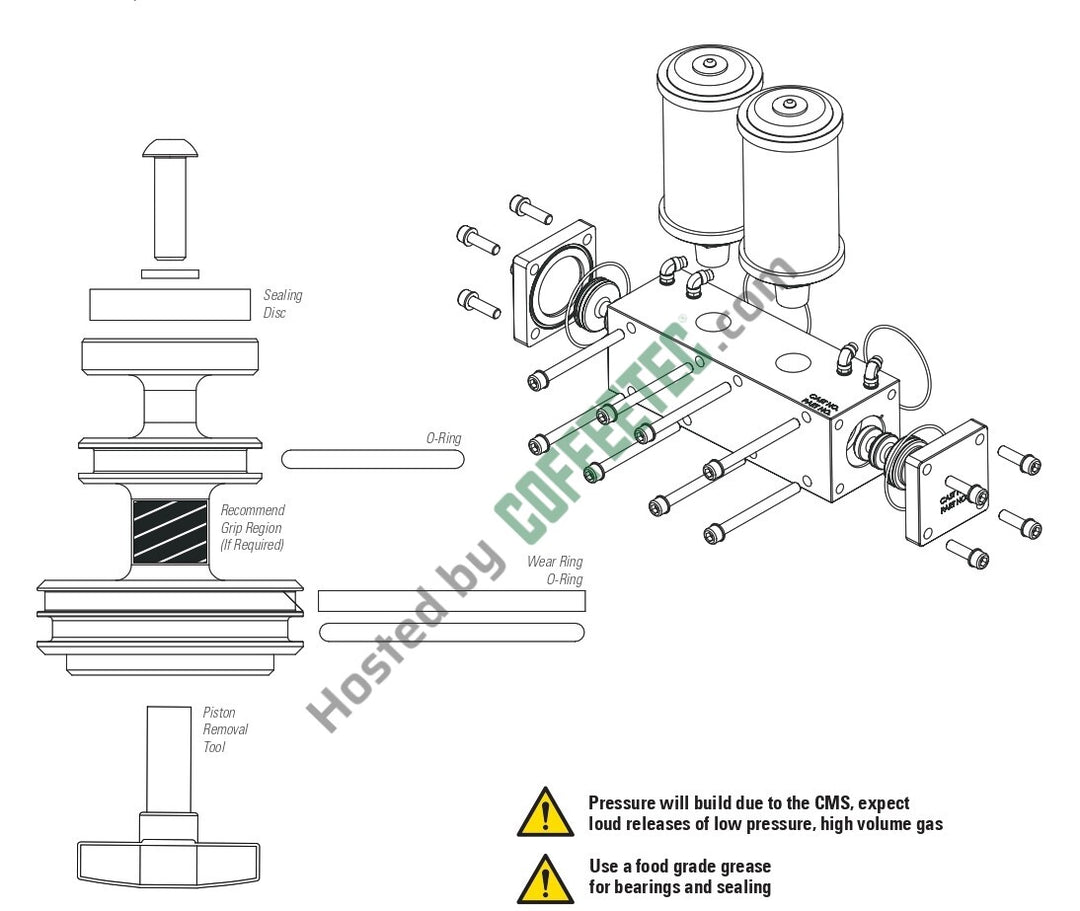

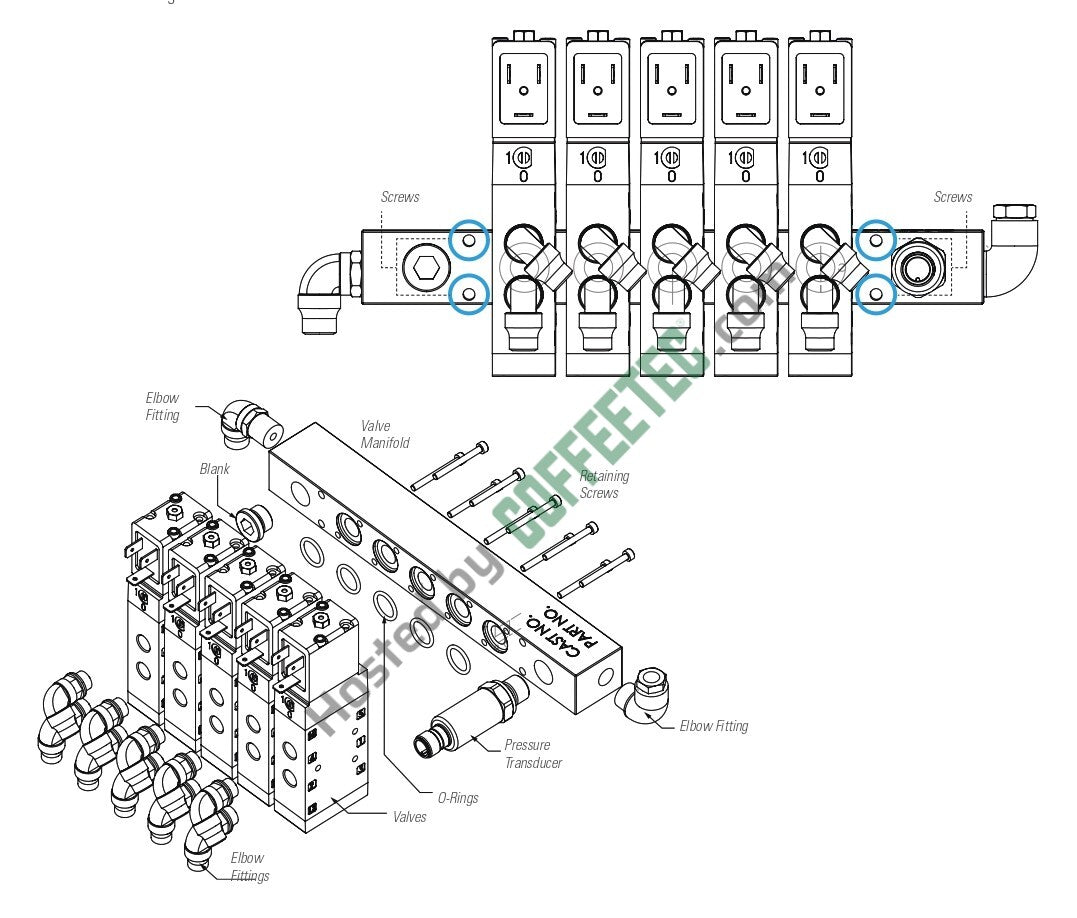

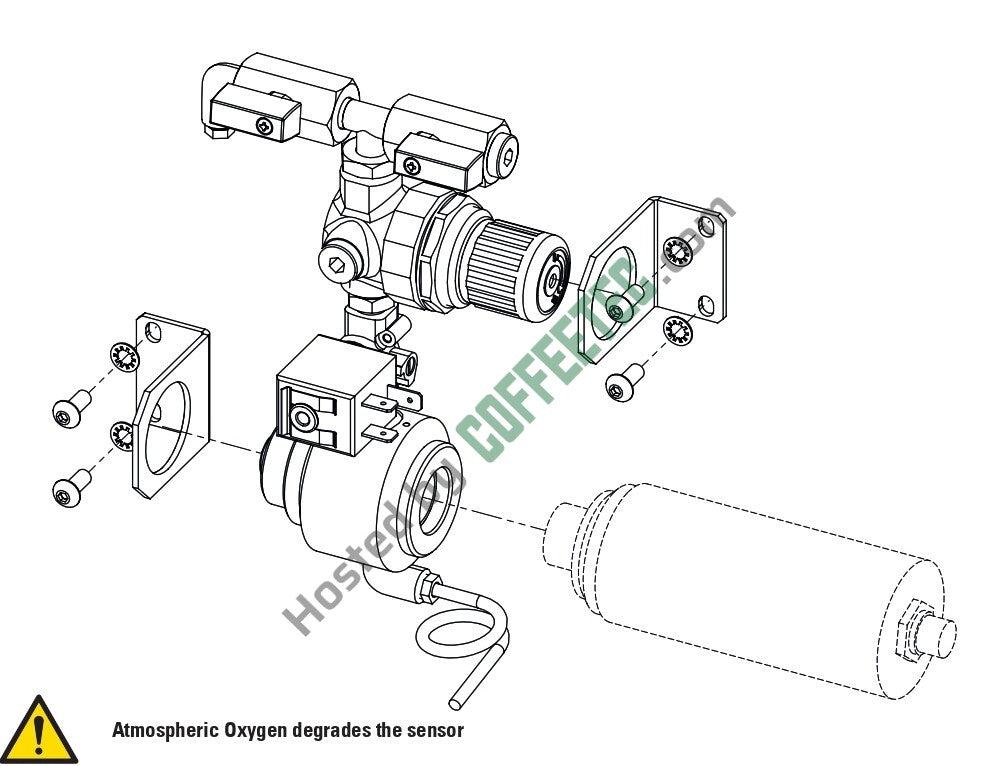

Engineering Drawings

Why choose us?

Comprehensive Solutions

From equipment and financing to consulting and education, we’re your one-stop shop

Unmatched Inventory

Explore over 3,000 new and used coffee roasting items—the largest collection online

Decades of Expertise

Benefit from our pioneering legacy and deep industry knowledge

Global Reach

Access the latest coffee tech from the U.S., Europe, and Asia.

Customer-Centric Approach

We are focused on long-term partnerships and your success

Active Community Engagement

We are proud participants in industry events and associations