3 kilo: Joper Cast Iron Roaster - PLEASE CALL OR EMAIL FOR QUOTE

Sorry, this item is sold. But we're here to help! We may have other equipment that isn't on the site yet, so let us know what you need and we'll help you find it.

Contact us, USA 800-999-1600, International +1-650-556-1333Designed for rugged efficient coffee, industrial style roasting. JOPER use durable cast iron and carbon steel material with insulated firebox and insulated roast chamber for a very quiet, efficient energy operation, features new low nox burner.

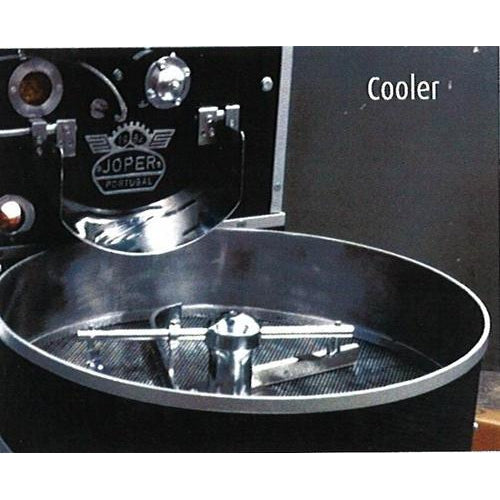

Multiple thermometers and temperature displays give the operator the incoming air and bean temp information. Its exclusive heat connection transfer and cooling systems make the JOPER an outstanding roaster. This roaster now has on-board cooling enabling simultaneous cooling and roasting. 4 on-board motors for total control and high productivity

Type:

- Model BSR 3 G - Gas Manual

- Model BPR 3 G - Gas with Roast Profile (Brigus)

- Model BSR 3 E - Electric:

Specifications/Technical Data:

- Load: 6.6 lbs (minimum recommended 2.2 lbs) or up to 26 lbs/hor

- Power 12 A 110 V / 60 Hz 1-phase or 220 V / 50 Hz 1-phase

- Weight 726 lbs 5 inch exhaust

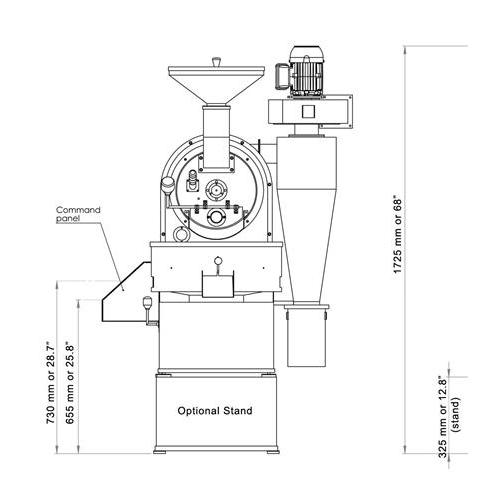

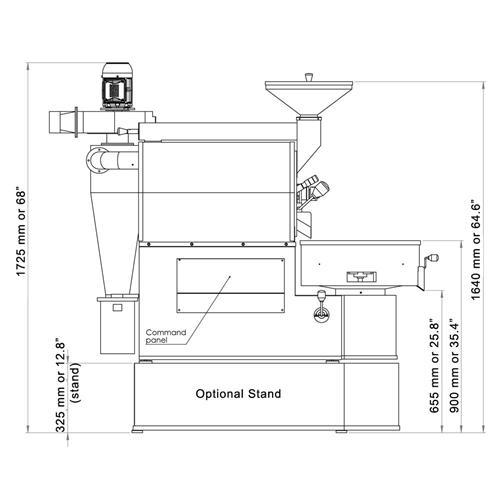

- Manual Model only The "footprint sizes" is 42" wide including remote chaff collector, 64" front to back including the chaff collector attached and 56" tall.

- Ships at 600 pounds - in crate of 48" x 70" x 62" Note: Crating and freight costs are not included. Origin is Europe.

- Burner Power: 51,000 BTU

Options:

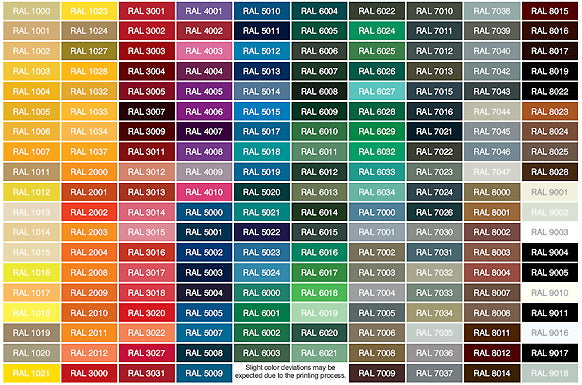

- Custom RAL colors

- Stand Available - raises the roaster 36" off the floor for optimal operating height. Stand is level with the drum. Color can be selected to match the roaster Built to UL295 Standards.

Profile Roast Control Option

Includes the advanced Brigus Coffee Roast Control & Logging System. This was specially created to work with the BPR family of roasters from JOPER. Together, they are the true master of coffee roast. BRIGUS (BRE 'gos) is a new type of coffee roasting control system. With it, attention and expertise will be concentrated on what matters:

Includes the advanced Brigus Coffee Roast Control & Logging System. This was specially created to work with the BPR family of roasters from JOPER. Together, they are the true master of coffee roast. BRIGUS (BRE 'gos) is a new type of coffee roasting control system. With it, attention and expertise will be concentrated on what matters:

- Define new profiles based on stored ones.

- The roast based on a pre-defined profile Manual or automatic process control

- Roasting vs. desired profile evolution during process

- Register occurrences, events and notes

- Record all process Analyze and compare roast batches

Information About the Profile Roast Control:

Notice the sound or noise that the roaster is making? It is very quiet! Color - $300.00 Standard color is black with silver but you can customize it to your hearts content using the colors below. When selecting the color for your Roaster Body . . . these RAL Colors are all available - your local Automotive paint shop will also have examples of the same. Choose and it will be done! Additional charge for Custom RAL Paint Colors.

Notice the sound or noise that the roaster is making? It is very quiet! Color - $300.00 Standard color is black with silver but you can customize it to your hearts content using the colors below. When selecting the color for your Roaster Body . . . these RAL Colors are all available - your local Automotive paint shop will also have examples of the same. Choose and it will be done! Additional charge for Custom RAL Paint Colors.

Front View of Roaster

Side View of Roaster